Revolutionising Manufacturing Through Integrated Digital Solutions

The manufacturing industry stands on the cusp of a new era, driven by the convergence of digital innovation and traditional methodologies. By embracing integrated digital solutions and prioritising sustainability, manufacturers can unlock new levels of productivity, efficiency, and competitiveness.

Manufacturing has long been a bastion of innovation, with companies continually seeking ways to reduce costs, enhance product quality, and improve customer service. Over past decades, strategies such as Lean, total productive maintenance (TPM), total quality management (TQM), and Six Sigma have delivered tangible results for industry leaders like Toyota, Procter & Gamble, and Danaher, boosting productivity by 6% or more annually.

Today, traditional approaches alone are no longer sufficient to maintain competitiveness; companies must integrate digital solutions to propel their operations into the future:

- Evolving Manufacturing Paradigms: The advent of digital and Industry 4.0 technologies marks a significant turning point for manufacturing. Artificial intelligence, self-learning production units, and interconnected supply chains offer unprecedented opportunities for next-generation production systems. When effectively deployed, these technologies can drive productivity gains exceeding 10% while enhancing flexibility, quality, and sustainability.

- Challenges and Opportunities in Manufacturing: Despite the promise of digital innovation, manufacturers face a host of challenges, including sustainability imperatives, heightened competition, and evolving customer expectations. To thrive in this dynamic environment, companies must adopt a more innovative approach to supply and production systems, integrating traditional methodologies with cutting-edge digital capabilities.

- Integrating Sustainability into Production Systems: Sustainability has emerged as a top priority for manufacturers worldwide, driven by increasing pressure from stakeholders and regulatory bodies. Addressing complex sustainability challenges requires a holistic approach that integrates digital technologies across the entire value chain. By embedding sustainability and circularity principles into core systems, manufacturers can not only achieve their production goals but also make a positive impact on the environment.

- Designing the Factory of the Future: Central to this paradigm shift is the concept of the “factory of the future,” a seamlessly integrated ecosystem that combines strategic principles with innovative tools. From individual workstations to the broader value chain, this approach redefines how products are designed, produced, and delivered to market. By leveraging digital technologies and embracing sustainability as a core pillar, manufacturers can position themselves as leaders in the industry.

- Key Elements of Future-Ready Production Systems: Future-ready production systems encompass a diverse array of elements designed to optimise operations and enhance sustainability. These include smart production processes, circular value streams, and synchronised supply chains, each tailored to the specific needs of the industry. By adopting a targeted approach that builds upon existing standards and integrates new digital technologies, manufacturers can realise significant value and achieve their production system goals.

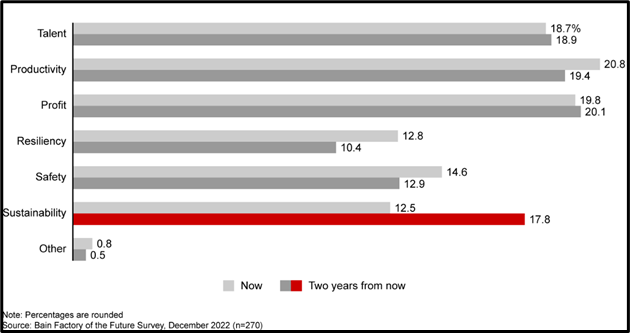

Image: Share of executives in the Manufacturing sector who identify these as their primary priority;

Source: Bain & Co.

- Tailoring company-specific approaches: While the principles of future-ready production systems are universal, their application must be tailored to the unique requirements of each company. By assessing industry-specific challenges and opportunities, companies can identify the most relevant elements and prioritise their implementation. Moreover, building upon existing standards and integrating digital technologies allows companies to leverage their current capabilities while laying the foundation for future growth.

- The Journey to Autonomous Manufacturing: At the forefront of this transformation is the concept of autonomous manufacturing, characterised by digitally-enabled shop floors and adaptive organisations. By embracing flexible plant layouts, robust value chains, and AI-supported problem-solving, companies can streamline operations and drive continuous improvement. However, realising this vision requires careful consideration of costs, benefits, and technological requirements, ensuring a smooth transition to the factory of the future.

The convergence of digital innovation and traditional methodologies heralds a new era for manufacturing. By embracing integrated digital solutions and prioritising sustainability, companies can unlock unprecedented levels of productivity, efficiency, and competitiveness.

As we embark on this journey towards the factory of the future, adaptation and evolution are paramount. By harnessing the power of technology and redefining production paradigms, manufacturers can shape a more sustainable and agile future. It’s a journey marked by challenges and opportunities, but with strategic integration and innovation, the future of manufacturing holds immense promise for those willing to embrace change.

Know more about the syllabus and placement record of our Top Ranked Data Science Course in Kolkata, Data Science course in Bangalore, Data Science course in Hyderabad, and Data Science course in Chennai.