Agentic AI: The Gamechanger for Supply Chains in the Era of Tariff Wars

Agentic AI revolutionizes supply chains by enabling autonomous systems to perform critical tasks such as adapting to market shifts, rerouting shipments, negotiating with suppliers, and mitigating risks in real time – all without human intervention

The US-China trade war under Trump has forced companies like Jaguar Land Rover, Audi, and Stellantis to halt shipments/production in North America, while Lindt & Sprüngli rerouted Canadian chocolate supplies from US to European factories to bypass retaliatory tariffs. Global supply chains are rapidly adapting to new tariff realities. Amazon canceled orders for beach chairs, scooters, air conditioners and other products from multiple vendors based in China and other Asian countries, Bloomberg reported. And with AI and generative AI already deployed in supply chain and inventory management by companies like Walmart and Alibaba, agentic supply chain and inventory management bots are the next step. They will negotiate with suppliers and distributors to coordinate deliveries, restocking and optimizing the use of warehouse space.

The year 2025 has barely begun, and supply chain leaders are already bracing for impact. According to a recent IBM Institute for Business Value (IBV) survey, 61% of Chief Supply Chain Officers (CSCOs) rank geopolitical risks as their top concern, while 58% cite global trade tensions as a major threat. The reason? A resurgence of tariff wars, escalating economic nationalism, and unpredictable policy shifts are disrupting global trade flows.

The World Trade Organization (WTO) warns that escalating tariffs could shave off 1.4% of global GDP by 2026, equivalent to $1.4 trillion in lost economic output. Meanwhile, a McKinsey report (2024) estimates that reshoring and tariff-driven supply chain reconfigurations could cost companies up to 30% more in operational expenses.

To learn how AI is impacting supply chain operations, the IBV in partnership with Oxford Economics, surveyed more than 300 global CSCOs and Chief Operations Officers (COOs) from organizations implementing AI-enabled automation. This research brief shows how organizations are moving through a continuum of progressively greater capabilities, built on AI. It starts with AI process automation and machine learning; advancing to generative AI in supply chain workflows, delivered by assistants; and evolving into agentic AI-enabled supply chains that operate autonomously and adapt dynamically in real time to real-world events.

For businesses, this isn’t just about higher costs – it’s about volatility, delays, and lost opportunities. But what if AI could turn this crisis into a competitive advantage? The study opens with an optimistic intro proclaiming; “Agentic AI is supercharging supply chain automation, accelerating process efficiency faster than humanly possible, and taking growth to the next level.” Agentic AI is like a self-driving assistant for businesses – it doesn’t just follow instructions but makes smart decisions on its own to solve problems.

The survey quotes CXOs who are expecting to deliver on the promise of Agentic Ai to help their organizations navigate the Tariff Turbulence by giving them valuable insights into the data from their supply chains. For instance, 62% of supply chain leaders recognize that AI agents embedded into operational workflows accelerate speed to action, hastening decision-making, recommendations, and communications. AI automation is happening faster than you think. Almost 70% of executives state that by 2026, their employees will be able to drill deeper into analytics to support real-time analysis and optimization as AI agents automate operational processes, especially in procurement and dynamic sourcing. Process efficiency gets an AI boost and 76% of CSCOs say their overall process efficiency will be improved by AI agents that perform repetitive, impact-based tasks at a faster pace than people can.

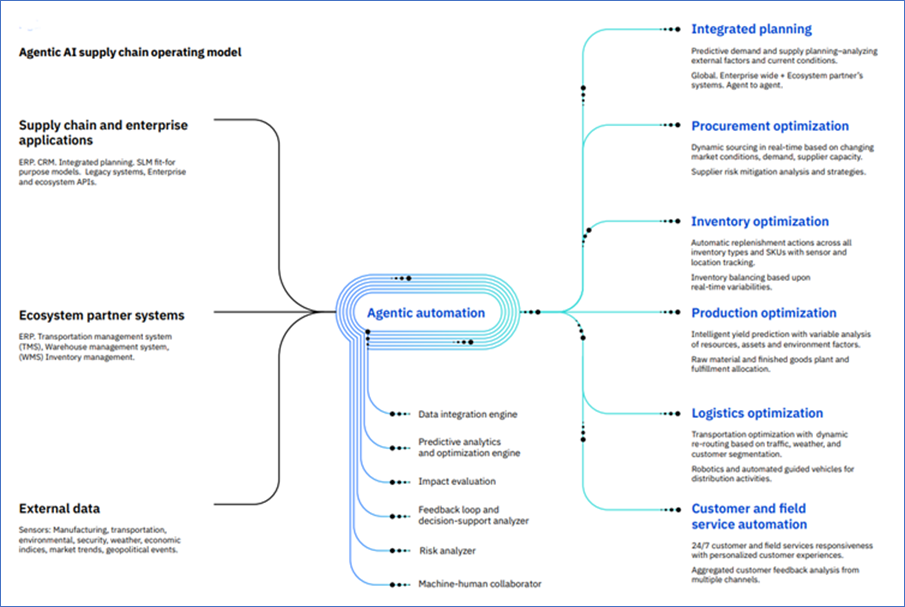

Image: Agentic AI supply-chain operating model; Source: IBM

The survey finds that agentic AI technology is enabling supply chain organizations to build a comprehensive agentic AI operating model (see graphic). Configured to meet the dynamic, data-driven, and complex requirements of supply chain operations, this model represents a new way for supply chain leaders to achieve operational resilience, not only inside their own organizations but across entire partner ecosystems.

The reason agentic AI operating model capabilities extend beyond AI automation and assistance is fundamental – these models are powered by much more data from many more sources. Agentic AI models start with operational data from ERP applications and fit-for-purpose supply chain apps. They also include agent-to-agent interfaces with ecosystem partners and tap into external data sources, such as weather reports, market indexes, and geopolitical events.

Agentic AI revolutionizes supply chains by enabling autonomous systems to perform critical tasks such as adapting to market shifts, rerouting shipments, negotiating with suppliers, and mitigating risks in real time – all without human intervention. These systems leverage integrated data engines to drive predictive analytics, optimize workflows, and evaluate risks, while dynamically adjusting procurement strategies based on real-time market demand and supplier capabilities. By handling operational complexities, agentic AI frees human teams to focus on strategic initiatives and customer relationships, fostering collaboration across departments and partner ecosystems. Early implementations highlight its potential in areas like dynamic sourcing, with future applications expected to expand into sustainability and compliance, positioning agentic AI as a self-optimizing backbone for modern, agile supply chains.

Acknowledgement: